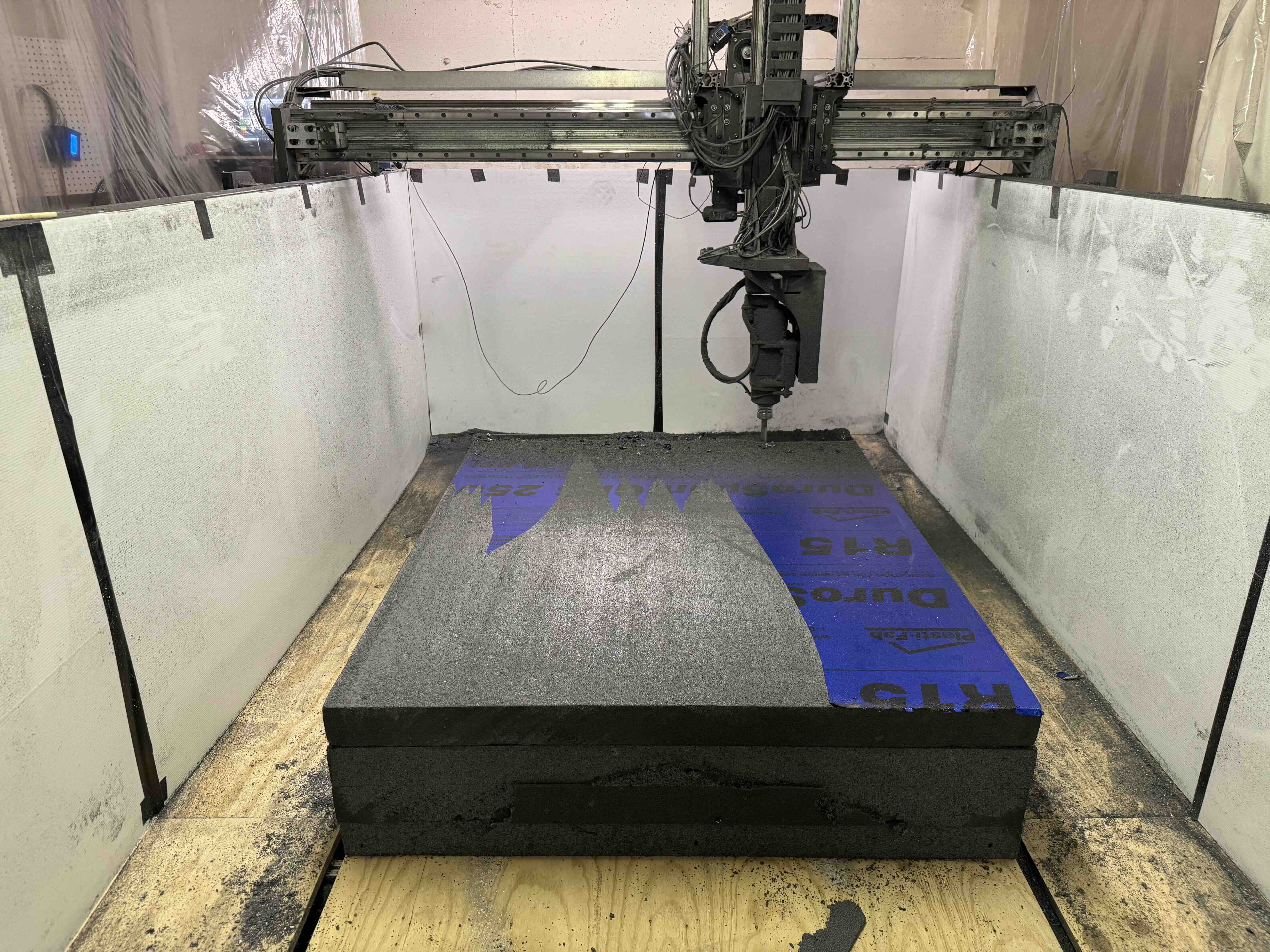

Arma is offering builders precision CNC-cut foam moulds and formwork for automotive projects. Using medium-density, cost-effective 2 lb/ft³ foam, our CNC router delivers accurate, high-quality shapes ready for mould making. Services are billed based on materials plus machine time, with flexible finishing options—from raw cut foam to sanded and coated surfaces for a smooth, production-ready finish.

Service Details: PDF Download

Arma’s 5-axis CNC routing service opens the door to projects that would be impossible or prohibitively expensive to shape by hand. Automotive builders can take advantage of precision-cut foam moulds to produce custom body panels—fenders, hoods, wings, side skirts, diffusers, and other aerodynamic components. Whether it’s restoring a classic, prototyping a one-off concept, or developing performance upgrades, our process delivers accuracy and repeatability.

Beyond cars, our machines are equally valuable in other industries. Designers and fabricators can create tooling, jigs, and composite moulds for production. Architects and artists can realize bold, sculptural forms for installations, facades, or exhibits. Marine and aerospace builders can generate lightweight moulds for hulls, fairings, or interior panels. Even furniture designers, product developers, and creative studios can benefit from the ability to shape large, complex forms quickly and consistently.

In short, if you can imagine it, we can cut it. From high-end automotive parts to large-scale art pieces, our 5-axis CNC routing provides a fast, reliable path from concept to physical form.

Arma’s 5-axis CNC routing service is priced to provide clear value while ensuring every project is handled with care and precision. We’ve designed our pricing structure to be straightforward, so you know what to expect without hidden costs.

Machine Time – $100/hr CAD Our core rate covers active cutting time on the 5-axis CNC router. If the spindle is running, the machine is producing your part with accuracy and speed.

Manual Services – $44/hr CAD This covers all support work that makes your project possible: material purchasing and pickup, machine setup, sanding, refuse disposal, and careful packaging for shipment.

CAD/CAM Preparation – $75/hr CAD Most projects require some digital preparation before cutting. Whether we’re cleaning up a 3D file, generating tool-paths, or modelling forms from your concept, this ensures the router has precise instructions. Typical jobs require 2–8 hours depending on complexity.

Materials – Cost + Handling We supply quality foam as the default cutting material, billed at cost plus a modest handling allowance. Alternative foams or coatings (such as epoxy sealing) can be substituted if your project requires additional strength or a smoother finish.

We can machine your project in two different ways, depending on how you intend to use it:

Buck (Positive Form): A buck represents the exact shape of the final part. This is the standard method for creating moulds. The buck is finished smooth and hard, then used to make a high-quality negative mould in fibreglass, carbon fibre, or other composites. This process takes longer but produces professional results.

Direct Mould (Negative Form): We can also cut the inverted shape directly as a mould. This is faster and allows immediate part production, but finishing the inside surface is far more difficult. For high-quality or visible parts, we recommend the buck method.

Our 5-axis CNC router is designed for precision and flexibility. Projects that require complex geometry, smooth curves, or deep undercuts benefit from the additional reach and articulation compared to standard 3-axis machines.

Accuracy: Typical tolerances are within ±0.5 mm, more than sufficient for mould-making, composite tooling, and large-format prototypes. For smaller features or tighter requirements, accuracy can be further improved with specialized finishing passes.

Scale: We can machine large forms by sectioning them into cuttable blocks and reassembling them with precision alignment. This makes it possible to produce everything from small components to full body panels.

Flexibility: From positive bucks to direct negative moulds, we can adapt our process to your project’s needs. Foam densities can be selected based on desired surface quality and strength.

Our router capacity is 48” x 96” X 16”. Any model design that is larger will need to be split into separate parts and assembled after cutting to form the desired part.

Moulds need to be designed with edges in a way that allows parts to be released freely where the angles on all surfaces are not parallel. Small areas can have no draft but generally this makes removing parts more difficult.

Our tool path software cuts parts in a full sheet bi-directional raster pattern which appears as a zig zag over the surface of the stock material. Our default step over (distance between each pass of the router bit) is 0.035” or 0.889mm with a 0.25” ball nose bit.

In most cases this creates a very accurate surface finish on the top face and some sanding is needed on vertical edges particularly on edges along the Y axis.

There is a tool reach limitation on ridges facing down because of our minimum radius 25” ball nose bit. This means that the cutter can’t reach areas under the size of this radius. Outer edges facing up are reachable and will be cut with good accuracy.

We offer several levels of finishing tailored to the needs of each project. Foam components can be delivered in the following states:

Raw Machined Foam – Directly off the router with visible tool paths. Best for customers who wish to perform their own finishing or use the piece strictly as a plug or buck.

Sanded – Light sanding to smooth rough tool marks and provide a more uniform surface. Suitable for basic shape verification, mock-ups, or display models that do not require surface coatings.

Epoxy-Sealed – Sanded surfaces with a coat of epoxy applied to harden and stabilize the foam. This reduces porosity, improves durability, and creates a more robust base for additional finishing or for use in moderate-duty moulds.

Fully Smoothed (Mould-Ready) – Precision sanding, epoxy sealing, and additional smoothing steps to achieve a hard, consistent finish. This level is designed to minimize further surface prep and is recommended for customers making composite moulds or production-quality parts.

Recommended Uses

Composite Production: For layups and high-quality parts, we strongly recommend epoxy-sealed or fully smoothed finishes. These provide the hard, non-porous surfaces necessary to achieve accurate moulds and durable tooling.

Display Models / Concept Forms: Sanded finishes are often sufficient for visual presentations, scale models, or design mock-ups. Raw machined foam may also be acceptable if the project only requires general shape verification without a focus on surface quality.

Raw unfinished forms will have ruff edges and faces that require sanding and finishing. A ruff cut part is the lowest cost option however we recommend that the parts are lightly sanded with an epoxy coat to help protect the part from damage if it is being shipped.

Light sanding and epoxy coating is an additional option we offer that requires a few hours of labour but adds to the durability of parts during shipping. Note that these parts require more fill and sanding before they can be used to make moulds or parts. One layer of epoxy increases the hardness and durability of the surface detail.

Finished forms take approximately one week as there are many coats and sanding each requiring a twenty four hour curing period. Finished parts are ready for mould making. If you have any questions about working with composite we recommend that you reach out to us.

Shown are some parts made from moulds.

|